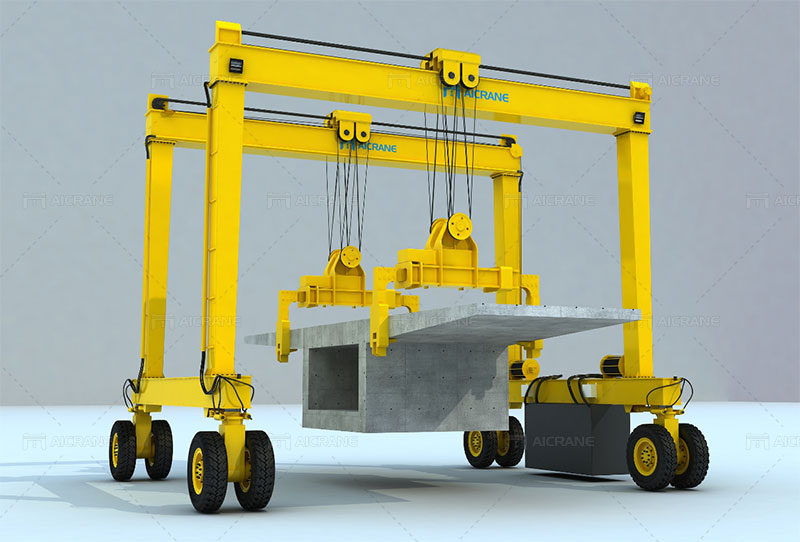

The construction industry has witnessed remarkable advancements in recent years, with technology playing a pivotal role in enhancing efficiency and safety across various construction processes. One such innovation that has transformed the way precast concrete beams are lifted and transported is the Rubber Tyred Gantry (RTG) crane. The integration of RTG cranes into construction sites has brought about a paradigm shift in the efficiency, flexibility, and safety of precast beam lifting operations.

Introduction to Rubber Tyred Gantry Cranes

Rubber Tyred Gantry cranes are a type of gantry mobile crane specifically designed for handling heavy loads in ports, logistics yards, and increasingly, in construction sites. The defining feature of these cranes is their rubber tires, which provide excellent mobility and allow them to move freely in various directions. RTG cranes are equipped with a cabin where operators control the crane’s movements, making them highly versatile and efficient for different lifting tasks.

Precast Beams in Construction

Precast concrete beams are a crucial component in modern construction projects. They offer numerous advantages, such as faster construction, improved quality control, and reduced on-site labor requirements. However, handling and lifting these heavy precast elements can pose significant challenges due to their weight and dimensions. Traditional lifting methods often require specialized equipment, extensive manpower, and intricate logistical planning.

The Role of RTG Cranes in Precast Beam Lifting

RTG cranes have emerged as a game-changer in the realm of precast beam lifting. Their versatility, mobility, and lifting capabilities make them an ideal choice for efficiently managing heavy precast beams in construction sites. Here are some key ways in which RTG cranes revolutionize precast beam lifting:

1. Mobility and Maneuverability:

RTG cranes are equipped with rubber tires that enable them to move smoothly on various surfaces, including rough terrains. This mobility eliminates the need for complex and time-consuming transportation arrangements, as tyre mounted gantry cranes can access even the most challenging construction sites without requiring extensive groundwork or infrastructure modifications.

2. Flexible Lifting Capabilities:

RTG cranes are designed to handle a wide range of loads, making them suitable for lifting precast beams of varying sizes and weights. Their adjustable spreader beams and lifting attachments can be customized to match the specific requirements of different precast beam designs, allowing for precise and safe lifting operations.

3. Improved Efficiency:

Traditional methods of lifting precast beams often involve multiple steps and equipment changes. RTG cranes streamline this process by offering all-in-one solutions for lifting, moving, and placing precast elements. This integration leads to substantial time savings and increased overall efficiency on construction sites.

4. Enhanced Safety Measures:

Safety is a paramount concern in construction projects, especially when dealing with heavy loads. RTG cranes come equipped with advanced safety features, such as load monitoring systems, anti-sway technology, and collision avoidance mechanisms. These features mitigate the risk of accidents and ensure the protection of workers and valuable construction assets.

5. Precise Placement:

The cabin of an RTG crane offers operators excellent visibility and control over the lifting operation. This enables precise placement of precast beams, even in confined spaces or complex construction layouts. The ability to accurately position beams enhances the overall quality of construction while reducing the need for costly adjustments later on.

6. Reduced Labor Dependency:

The use of RTG cranes significantly reduces the need for extensive manual labor during precast beam lifting. This not only cuts down on labor costs but also minimizes the physical strain on workers, leading to improved overall worker well-being.

Conclusion: A New Era of Precast Beam Lifting

The incorporation of Rubber Tyred Gantry cranes into construction sites marks a significant leap forward in precast beam lifting operations. These gantry cranes bring unmatched mobility, versatility, and safety to construction projects, resulting in increased efficiency, reduced costs, and improved overall project outcomes. The construction industry is embracing this technology as it continues to strive for excellence in managing heavy loads with precision and ease. As technology evolves, it’s likely that Rubber Tyred Gantry cranes will continue to play a pivotal role in transforming construction practices and shaping the future of the industry.