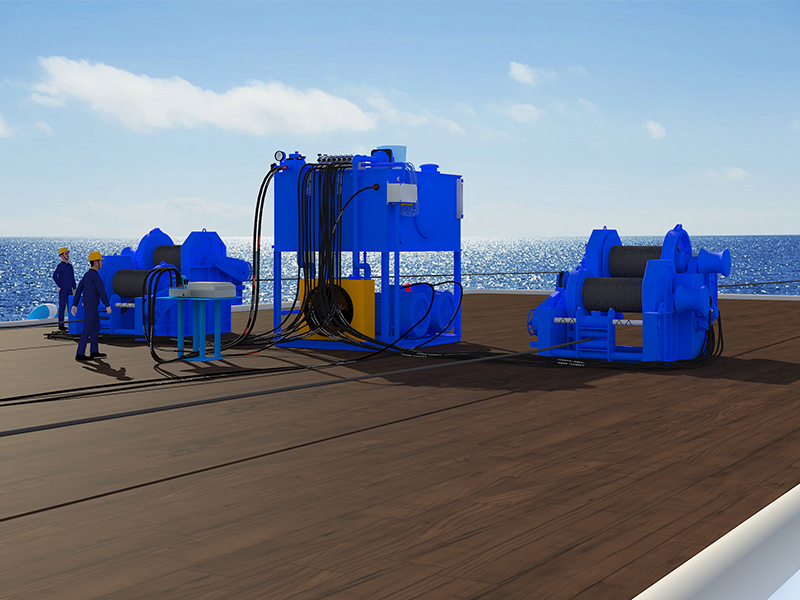

Marine winches are indispensable tools in the maritime industry, serving a multitude of functions from anchoring and towing to lifting heavy loads. The capacity of a marine winch is a critical factor that determines its effectiveness and suitability for specific tasks. In this article, we delve into the intricacies of how the capacity of a marine winch is determined, exploring the key factors and considerations that engineers and operators must take into account.

Understanding Winch Capacity:

The capacity of a marine winch refers to its maximum load-bearing capability. It is the pivotal parameter that dictates the safe and efficient operation of the winch marine. Unlike onshore winches, marine winches operate in dynamic and challenging environments, facing the relentless forces of the sea. Determining the capacity requires a comprehensive analysis of the forces at play during various maritime operations.

1. Load Dynamics:

The first and foremost consideration in determining winch capacity is understanding the dynamics of the loads it will handle. Marine winches may be employed for diverse tasks such as lifting cargo onto a ship, deploying and recovering subsea equipment, or towing other vessels. Each operation imposes distinct loads on the winch, and these loads can vary based on factors like weight, size, and the nature of the objects being handled.

For instance, when lifting a heavy load from the seabed, the winch must contend with the weight of the object, water resistance, and potential dynamic forces caused by currents or waves. A thorough understanding of these dynamic loads is essential for engineers to specify a winch with an appropriate capacity that ensures both safety and operational efficiency.

2. Working Load Limit (WLL):

The Working Load Limit (WLL) is a crucial parameter used to express the maximum load that a winch is designed to handle under normal working conditions. WLL takes into account factors such as the strength of the winch components, the material and size of the rope or cable used, and the environmental conditions. It is a conservative value intended to ensure the winch’s durability and safety, allowing for a margin of safety in real-world operations.

The WLL is determined through rigorous testing, considering factors like the breaking strength of the winch components and the anticipated loads the winch will encounter. It is important for operators to adhere strictly to the WLL to prevent overloading, which could lead to equipment failure and compromise safety.

3. Rope or Cable Selection:

The type, material, and size of the rope or cable used with the winch offshore play a pivotal role in determining its capacity. Different applications may require specific types of ropes, such as wire ropes, synthetic ropes, or hybrid combinations. The strength and elasticity of the rope are critical factors in managing loads and absorbing dynamic forces.

Engineers must carefully calculate the safe working load of the chosen rope and ensure that it aligns with the winch’s capacity. The rope should have sufficient strength to handle the anticipated loads without risk of breaking or stretching beyond safe limits.

4. Line Pull and Drum Capacity:

The line pull, measured in pounds or kilograms, is the force exerted by the winch on the rope or cable. It is a key factor in determining the winch’s capacity. The line pull requirement is influenced by the weight of the load and the forces encountered during operations.

Additionally, the drum capacity, or the amount of rope or cable that can be wound onto the winch drum, is a critical consideration. The drum must have adequate capacity to accommodate the length of rope required for specific tasks. Insufficient drum capacity can limit the winch’s functionality and compromise its ability to handle loads effectively.

5. Power Source and Drive System:

The power source and drive system of the winch also contribute to its overall capacity. Hydraulic, electric, and pneumatic systems are common in marine winches, each with its advantages and limitations. The power source must be capable of delivering the necessary energy to drive the winch under varying loads and conditions.

The drive system, whether it’s a hydraulic motor, an electric motor, or another type, should be matched to the anticipated loads and operational requirements. The efficiency and torque characteristics of the drive system directly impact the winch’s performance and capacity.

6. Environmental Conditions:

Marine environments are notoriously harsh, with factors like saltwater exposure, temperature variations, and corrosive elements posing additional challenges. The winch must be designed and constructed to withstand these conditions without compromising its capacity over time. Corrosion-resistant materials, protective coatings, and robust sealing mechanisms are integral to ensuring the longevity and reliability of the winch in marine settings.

7. Regulatory Standards:

Compliance with industry standards and regulatory requirements is paramount in determining the capacity of marine winches. Various organizations, such as the International Organization for Standardization (ISO) and the American Bureau of Shipping (ABS), provide guidelines and standards that set criteria for winch design, testing, and capacity calculations. Adhering to these standards ensures that winches meet established safety and performance benchmarks.

Conclusion:

In conclusion, determining the capacity of a marine winch is a multifaceted process that involves a thorough analysis of the dynamic forces at play during diverse maritime operations. Engineers must consider load dynamics, working load limits, rope or cable selection, line pull, drum capacity, power sources, environmental conditions, and regulatory standards to design winches that are not only powerful but also safe and reliable in the challenging marine environment. As technology advances and industry demands evolve, the science behind determining marine winch capacity continues to progress, driving innovation and ensuring the efficiency and safety of maritime operations worldwide.